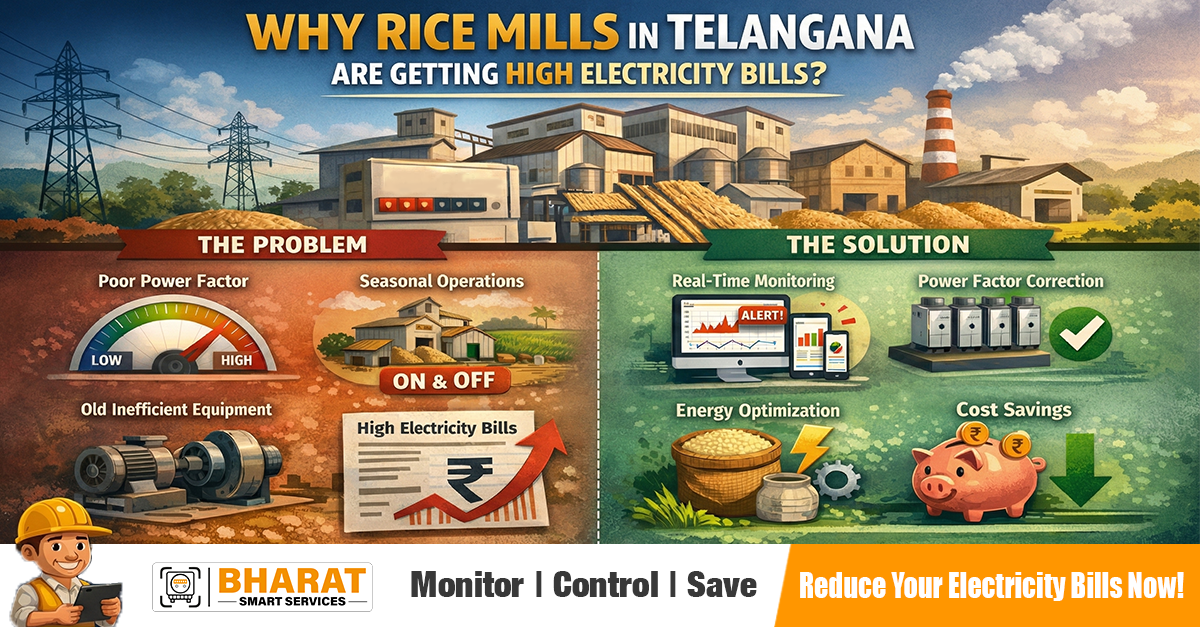

Why Rice Mills in Telangana Are Getting High Electricity Bills - And How to Reduce Them ?

Facing high electricity bills in your rice mill? Understand how unblocking kVArh lead impact costs and how Bharat Smart Services helps reduce your bill.

If you run a rice mill in Telangana, you may have noticed something frustrating lately:

Your electricity bill has increased even when your production hasn’t.

Since the introduction of update in kVAh billing by unblocking kVArh lead factor , many rice mill owners are seeing higher bills — especially seasonal mills and mills without proper power factor management.

This blog explains why this is happening, what has changed in billing, and how rice mill owners can reduce their electricity bills in a smart and sustainable way.

Why Are Rice Mills More Affected by the New Billing System?

Rice mills operate very differently from other industries:

- They run heavy motors for polishers, elevators, blowers, and compressors.

- They operate seasonally, not continuously throughout the year.

- Machines start and stop frequently based on paddy availability.

- Load fluctuates significantly between peak milling hours and idle time.

This operating pattern creates multiple inefficiencies that now directly impact billing.

Note: You are now billed not only for the useful energy you consume, but also for inefficient and unstable electrical behaviour.

All the Major Reasons For Rice Mills Getting Higher Bills

No APFC or Improper Power Factor Management

Without automatic correction, power factor drops during partial loads, increasing reactive energy and billed units.

Fixed or Poorly Sized Capacitor Banks

Many mills have fixed capacitors that:

- Over-compensate at low load (creating excess kVArh lead

- Under-compensate at high load (creating kVArh lag)

- Cause frequent electrical imbalance

This instability increases kVAh and now directly increases billing.

Unblocking of kVArh Lead

Earlier, excess leading reactive power (generated by capacitors) was often ignored.

Now, with kVArh lead unblocking, this excess is:

- Measured

- Recorded

- Reflected in billing

Seasonal and Batch-Based Operations

When mills operate partially or intermittently:

- Power factor becomes unstable

- Capacitors do not match load

- Reactive energy increases

This makes seasonal mills more vulnerable than continuous-process industries.

Old or Inefficient Equipment

Old motors, blowers, and dryers consume more power and worsen electrical behaviour.

Lack of Visibility and Control

Most mills only see problems when the bill arrives — by then the loss has already happened.

Common Problems We See in Rice Mills

- Power factor dropping below recommended levels during partial or night operations

- Capacitors not switching properly

- Machines running idle between batches

- No monitoring of kVAh and kVArh lead/lag

- No alerts when something goes wrong

As a result:

The wastage silently adds to your bill — and you only realise it when the bill arrives.

How Bharat Smart Services Helps Rice Mills Reduce Electricity Bills

At Bharat Smart Services, we help rice mill owners understand, control, and optimise their electricity usage.

We don’t just show data — we give clear actions.

What we do:

- Monitor your energy usage daily, not just monthly

- Track kVAh, power factor, and kVArh lead & lag trends

- Detect abnormal behaviour and inefficiencies early

- Alert you when corrective action is needed

- Help you stabilise electrical behaviour and avoid penalties

In simple words:

We help you stop paying for wasted electricity.

What You Should Do Immediately

If your rice mill Electricity bill has increased:

Do not wait for the next bill cycle.

Do not add random equipment without understanding the cause.

The first step is visibility.

Reach out to Bharat Smart Services to:

- Analyse your current energy behaviour

- Identify the exact cause of high billing

- Take corrective action before the next bill